Choosing the Right Pump - Key Performance Specs

What's are the key specs to consider when choosing a pump?

The learning curve’s about to get a little steeper. But this is all important info to know and think about before you make any decisions.

There are four key components that drive a pump’s performance- engine size, impeller, flow rate and head pressure.

Each plays a crucial role in determining how well a pump can handle specific tasks- whether that’s moving water, handling debris, or operating in challenging conditions.

Engine Size - Power Required To Push

You need to choose a pump with an engine that’s up to the job. Seems simple, and with Honda pumps, it is!

Honda engines are legendary, and they’re a key reason why Honda Pumps are so good.

These GX engines are engineered for durability and consistent performance, ensuring smooth operation even in tough conditions, like flood control, or industrial environments.

The majority of Honda’s GX engines are Overhead valve (OHV) offering several advantages including:

a simpler design

compact size thanks to its offset cylinder

large easy fill petrol reservoir

and a lower lubrication requirement.

They are also known for their ability to produce more torque at low speeds, and for their impressive throttle governing which allows the user greater control over the discharge volume of their pump.

All Honda pumps use a built-in fan and shroud to direct cool air over the engine, preventing overheating when under load. The splash lubrication system eliminates the need for an oil pump and simplifies engine design meaning less drag, less weight and less moving parts.

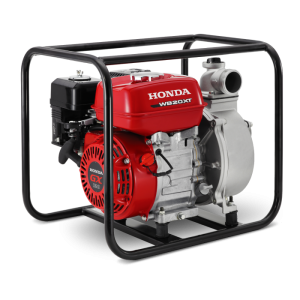

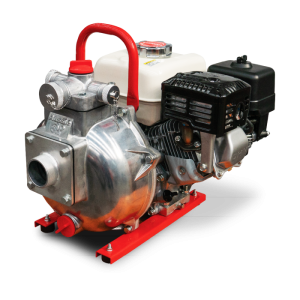

Honda pumps (like both of these) often come with oil alert systems that automatically shut down the engine if the oil level is too low, helping prevent engine damage due to insufficient lubrication.

Honda Engine Matching

Honda carefully matches the engine to each pump’s specific application, and the intended performance specs.

This involves a lot of testing to optimise power output and efficiency, making sure it can maintain consistent pressure and stay cool under heavy workload.

Easy starting and fuel efficient

Honda’s GX engines are also known for being exceptionally fuel-efficient thanks to its superior OHV and combustion systems, enabling longer operation on less fuel, and feature an advanced decompression system that makes starting easier.

This clever system temporarily reduces compression during start-up, making it easier to pull the recoil starter. The engine turns over quickly – even in cold weather or when it’s been sitting idle for a while.

Honda’s advanced tech and durable components, such as a heavy-duty crankshaft and superior air filtration, like this pre foam filter before the main filter (points to where it is) all contribute to long-lasting reliability which will save you time and money.

The Impeller & Casing

The impeller is the part of the pump that moves the liquid from one place to another. So, pretty important!

It’s primary job is to convert mechanical energy from the engine into kinetic energy that propels water through the system.

Here’s a simple way to visualize it:

The engine spins the impeller (inside its casing)

The impeller blades move water outward from the centre of the pump, known as the eye of the impeller, this increases its velocity.

The water then flows out of the pump under higher pressure.

Honda Water Pump impellers are circular and disc-shaped, like a small wheel or fan, optimised for clean water. They have narrower vanes designed to push water efficiently.

Honda Trash Pump impellers have thicker and sturdier vanes designed to pass debris like mud, sand, and small rocks. These can handle more abrasive materials without getting damaged.

Now, let’s look at the impeller casing.

This is the outer shell that surrounds the impeller. Its job is to direct the flow of fluid and convert the velocity from the impeller into pressure.

The shape of the casing helps create the desired pressure and flow rate.

Honda pump casings are engineered for optimal performance and their corrosion-resistant alloy construction has better durability in harsh conditions. Honda Trash pump casings are easy to remove to ensure you keep the impeller clean of dirt and debris via 4 – 6 nuts, reducing Pump down time, making servicing easier.

Unlike many competitors, Honda casings are also resistant to cracking or warping; and they have high quality, corrosion-resistant rubber seals.

The wear plate on Honda Trash pumps further protects the pump casing from abrasion caused by the impeller and debris. Helping to maintain efficiency and prevent damage by acting as a sacrificial barrier.

Engineered for life

When you choose Honda power equipment, you gain access to a nationwide support network staffed by trained professionals dedicated to keeping your products running smoothly. Using only Honda genuine parts and accessories, our expert technicians ensure your equipment performs at its best, providing reliability and peace of mind every step of the way, Honda engineering for life.

Yes, you could find a cheaper one. But why would you want it?

So now you know a bit about impellers and casings.

The next two things to explore, performance-wise, are flow rate and head size - really important specs.

Flow Rate

The Pump’s Flow Rate tells you how much water it can move, measured as litres per minute (LPM). That’s pretty straightforward, right?

A higher flow rate is particularly important in situations where large volumes of water need to be moved quickly, like in a flooding or irrigation scenario.

Head size

Head size (or total head) is the term used to describe how high a pump can lift water.

It’s typically measured in feet and metres.

Head size is critical because it helps determine how well a pump can overcome elevation changes, or friction losses in pipes. (Yip, friction. Who knew?!)

Water Pumps with a ‘high’ head are best for applications where water needs to be moved vertically, or through long-distance piping systems.

Trash Pumps tend to have a lower head size. That’s because their design focuses on moving large volumes of debris-filled water, rather than lifting.

How’s your own head going? Ready for more? The next part’s a bit technical, you may need to press pause and get a coffee.

Getting the balance right

It's important to understand that head size and flow rate are inversely related.

As a pump pushes water higher, increasing the head size, the flow rate decreases, because the pump has to work harder against gravity. Physics!

A pump lifting water to a lower height will tend to have a higher flow rate. Also physics!

This is why it's crucial to balance the desired flow rate with the head size to ensure the pump will perform effectively for your needs.

If you’re still not sure about what you might need, Honda Outdoors has a handy online Pump Calculator to help you get all this right.